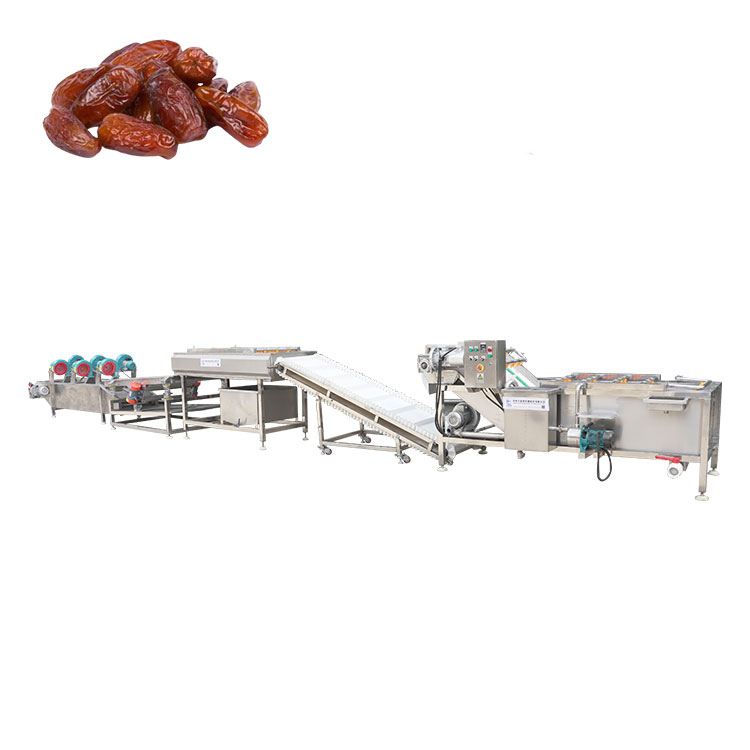

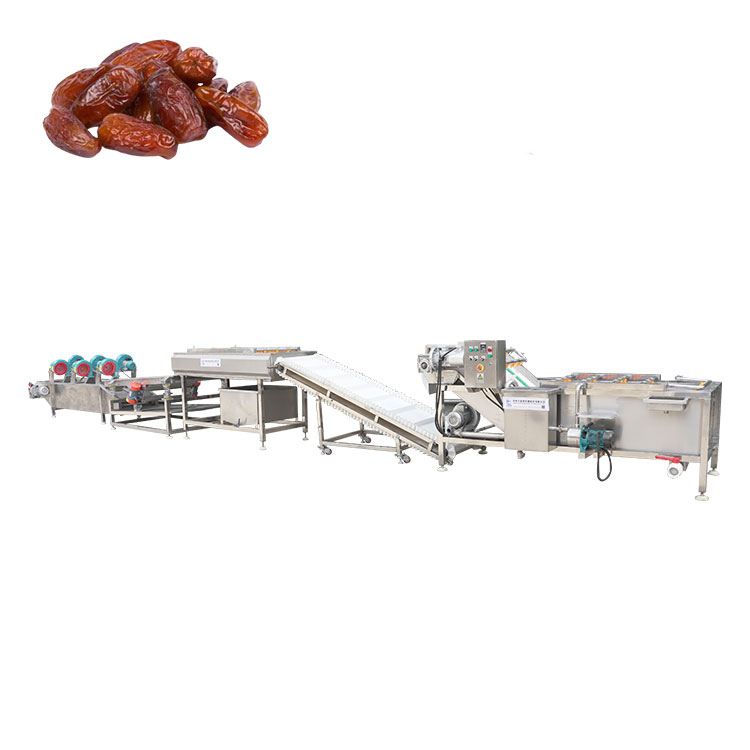

IL Turnkey Date Palm Washing, Grading, and Packing Processing Machine is an integrated, automated solution designed to streamline the transformation of raw date palms into market-ready products. This comprehensive system encompasses stages such as cleaning, essiccazione, classificazione, and packaging, ensuring that each date meets stringent quality standards. Constructed with food-grade stainless steel and equipped with advanced automation technologies, this processing line enhances operational efficiency, maintains product integrity, and reduces labor costs, making it an ideal choice for date producers aiming to optimize their processing operations.

Elevating → Bubble Washing → Brush Washing → Air Drying → Grading → Packaging

1. Elevating System

Transports raw dates to the processing line, facilitating a continuous and efficient workflow.

2. Lavatrice a bolle

Employs high-pressure air bubbles to gently remove surface contaminants without damaging the fruit.

3. Brush Washing Machine

Utilizes soft brushes and water sprays to clean residual impurities, especially from the folds of the dates.

4. Air Drying Machine

Dries the cleaned dates using ambient air, preserving their natural flavor and preventing microbial growth.

5. Macchina di classificazione

Sorts dates based on size and quality, ensuring uniformity in the final product.

6. Packaging Machine

Automates the packing process, sealing dates in various packaging formats ready for distribution.

|

Total output of date palm washing line 1000 kg / H

|

|

Articolo

|

Energia

|

Misurare

|

| macchina di sollevamento |

0.75kW/380 V/50 Hz

|

2000*1000*1900mm

|

| Lavatrice a bolle |

5.1KW/380 V/50 Hz

|

5000x1200x1300mm

|

|

Macchina per la pulizia dei rulli per capelli

|

2.0kW/380 V/50 Hz

|

2000*1000*1300mm

|

| macchina di smistamento |

0.75kW/380 V/50 Hz

|

3000*900*900mm

|

| macchina di sollevamento |

0.75kW/380 V/50 Hz

|

2000*800*1600mm

|

| macchina vibrante |

1.5kW/380 V/50 Hz

|

1500*1000*1300mm

|

| macchina per l'asciugatura dell'aria |

15kW/380 V/50 Hz

|

4000*1200*1400mm

|

| Nota: Questi parametri sono convenzionali e possono essere personalizzati in base alle esigenze del cliente |

Increased production capacity: The washing machine can process 3,000 kg of dried fruit per hour to cope with peak orders;

Cost savings: Reduce staff and increase efficiency, shorten production cycle, and reduce comprehensive operating costs by more than 20%;

Quality assurance: Gentle washing and low-temperature drying can maximize the retention of nutrition and taste, and increase terminal sales price;

Compliance export: Comply with HACCP and ISO standards, helping to open up high-end markets such as Europe, the United States, and the Middle East;

Reduce labor input: fully automated operation, reduce manual sorting and cleaning, and avoid cross contamination;

Efficient packaging: hot and cold sealing technology ensures vacuum packaging, strong sealing, and extended shelf life;

Homogeneous grading: high-precision sorting equipment ensures consistency in fruit size and quality, and improves market competitiveness;

Modular expansion: equipment can be flexibly increased or decreased according to production capacity requirements without overall transformation;

Energy saving and consumption reduction: closed circulating water system and air-drying recovery design significantly reduce water and energy consumption;

Bubble cleaning technology: high-pressure bubble circulation, thoroughly removes surface dirt and bacteria, no mechanical damage;

Scrubbing module: simulates manual hand grasping and rubbing, focusing on cleaning the wrinkles of the fruit to ensure no residue;

High-speed air drying device: vortex air pump low-temperature air drying, protects the fruit color and taste, high drying efficiency and quiet;

Integrated automatic processing line: integrates lifting, bubble cleaning, scrubbing, air drying, grading and packaging, reducing process connection links;

Food-grade stainless steel structure: all made of 304/316 stainless steel, corrosion-resistant, easy to clean, in line with international food safety standards;

dates palm washing line details in our factory

In summary, the Turnkey Date Palm Washing, Grading, and Packing Processing Machine offers a comprehensive solution that addresses the challenges of traditional date processing methods. By integrating advanced automation, it ensures consistent quality, enhances efficiency, and reduces operational costs, making it an invaluable asset for date producers aiming to compete in the global market.

Contact us today to learn more about how this processing line can transform your date production operations and to request a personalized quote.

Lavatrice per verdure

Lavatrice per verdure