The semi-automatic onion powder production line is a cost-effective solution designed for small and medium-sized onion powder production. The semi-automatic onion powder production line is designed to process fresh onions into high-quality onion powder. The system integrates key processing steps such as peeling, cleaning, trancher, séchage, grinding, sieving and packaging, while retaining manual control of key operations, ensuring flexibility and easy maintenance. Compared with the fully automatic production line, it retains manual operation at key links, taking into account cost control and production efficiency, and is suitable for small and medium-sized enterprises or start-up brands.

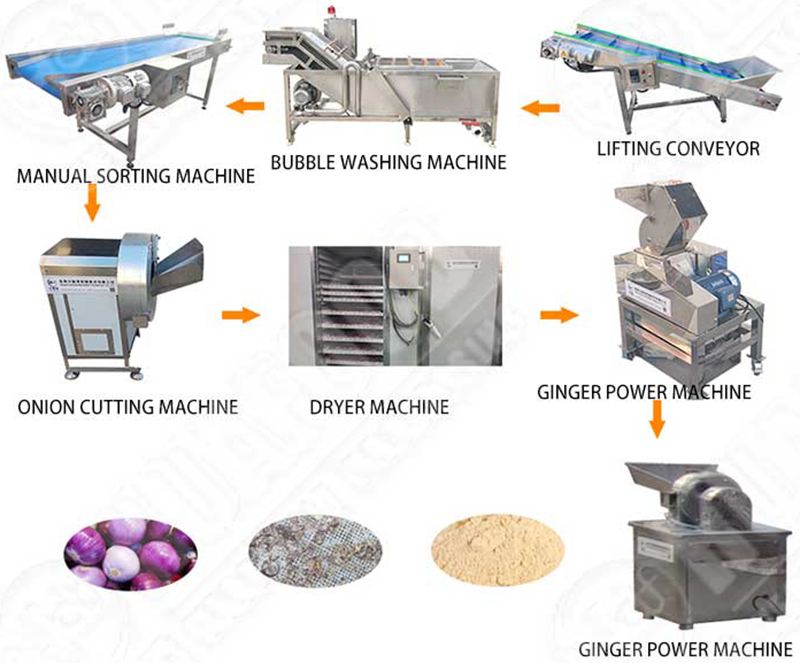

Onion Powder Making Production Process

Onion peeling → Onion washing → Onion slicing → Onion dehydration → Onion drying → Onion grinding → Screening → Packaging

Here is the onion powder production line youtube video working process in our factory for your reference!!

Onion peeling machine

Adopts the airflow principle to quickly remove the onion skin, maintain the integrity of the onion, and reduce losses.

Onion washing machine

Use bubbles and water flow to thoroughly clean the surface of the onion to remove dirt and impurities.

Onion slicer

Cut the washed onions into uniform slices with adjustable thickness to ensure uniform subsequent drying.

Onion dehydrator

Remove excess moisture from the surface of the onion slices through centrifugal force to prepare for the drying process.

Onion dryer

Uses low-temperature hot air circulation technology to evenly dry the onion slices and retain the original flavor of the onions to the maximum extent.

Onion grinder

Grind the dried onion slices into fine powder, which is fine and suitable for various food processing.

Sieving machine

Screen out coarse particles to ensure uniform fineness of onion powder and improve product quality.

Packaging machine

Automatically completes the weighing, packaging and sealing of onion powder to meet the packaging needs of different specifications.

Onion Powder Industry Outlook

The global onion powder market is experiencing significant growth, driven by the increasing demand for convenient and flavorful ingredients in processed foods, snacks, and seasonings. According to industry reports, the market is projected to expand steadily, with a notable compound annual growth rate (CAGR) over the forecast period. This growth is fueled by its widespread use in various culinary applications, reflecting a shift towards ready-to-use ingredients in the food industry.

Market size and growth: In 2024, the global onion powder market size has reached 73,100 tons, mainly driven by the increase in consumption in the processed food and catering industries.

Future forecast: By 2033, the market size is expected to increase to 98,700 tons, with a compound annual growth rate of 3.4%.

Growth drivers: including the growth of residents’ disposable income, the acceleration of urbanization, and the rising demand for convenience foods under the fast-paced lifestyle.

Segment trends: The plant-based and organic onion powder market segments are expanding rapidly, and consumers’ demand for non-GMO and high quality is constantly increasing.

Regional pattern: North America, Europe and Asia-Pacific are the main markets, and the focus of demand varies from region to region.

Semi-Automatic Line with Market Demand Alignment

Cost-effectiveness: The modular semi-automatic design significantly reduces the investment threshold for small and medium-sized enterprises, which is in line with the demand growth in emerging markets and second-tier markets.

Production flexibility: The semi-automatic operation mode supports on-demand adjustment of batches to meet the fluctuating demand of residents and institutions.

Quality assurance: Integrated dehydration and low-temperature drying technology effectively locks in the original flavor and nutrition of onions, responding to the demand for quality by high-end consumers.

Consistency control: The automatic grinding and screening system ensures uniform powder particle size, which meets the strict quality standards of developed markets.

Channel support: The automatic packaging function at the end of the production line improves production capacity and packaging efficiency, and helps the development of online retail and specialty distribution channels.

Energy consumption optimization: The energy-saving design effectively reduces operating costs and helps producers maintain competitiveness in a market environment where profit margins are compressed.

Customized processing: Manual control nodes are retained and can be flexibly set according to high-end demands such as organic and non-GMO to meet the rapid growth trend of market segments

Semi-Automatic Onion Powder Production Line Advantage

Cost Efficiency: Lower initial investment compared to fully automated systems.

Flexibility: Manual control allows for adjustments based on production needs.

Scalability: Easily expandable to meet increasing production demands.

Quality Control: Ensures consistent product quality with minimal labor.

Through the above docking, the semi-automatic onion powder production line is not only highly consistent with the industry trend in terms of production capacity, cost and quality, but also provides a practical growth engine for small and medium-sized producers. Welcome to leave a message online below to discuss with us how to seize the new blue ocean of the onion powder market with the help of this solution!

Machine à laver les légumes

Machine à laver les légumes