Are you tired of spending hours scrubbing and cleaning root vegetables by hand? Root vegetable cleaning machines have revolutionized the post-harvest processing of potatoes, البطاطا الحلوة, and carrots, significantly reducing labor costs and ensuring higher-quality output. As a farmer or a business owner in the agricultural industry, you might be interested in understanding the features, benefits, and working principles of these machines.

Features of Root Vegetable Cleaning Machines

Root vegetable cleaning machines are designed to remove dirt, حطام, and other impurities from the skin of root vegetables. They typically come with a conveyor belt that gently carries the vegetables through the cleaning chamber. The chamber is equipped with brushes or jets that efficiently scrub the vegetables clean.

Benefits of Using Root Vegetable Cleaning Machines

The primary benefit of using a آلة تنظيف الخضار الجذرية is the significant reduction in labor costs. Manual cleaning is a time-consuming and labor-intensive process, whereas machines can handle large quantities of vegetables in a short time. بالإضافة إلى ذلك, machines ensure a more consistent and thorough cleaning, resulting in a higher quality output. This, in turn, enhances the marketability of the vegetables and fetches a better price for farmers and business owners.

Working Principles of Root Vegetable Cleaning Machines

The working principle of root vegetable cleaning machines is quite straightforward. The vegetables are placed on the conveyor belt, which carries them into the cleaning chamber. Inside the chamber, brushes or jets rotate or spray water at high speeds, effectively scrubbing the skin of the vegetables. The impurities are washed away, and the clean vegetables exit the machine through another conveyor belt.

Operators can adjust the speed of the conveyor belt and the intensity of the brushes or jets based on specific requirements. This flexibility allows the machine to handle different types and sizes of root vegetables with equal efficiency.

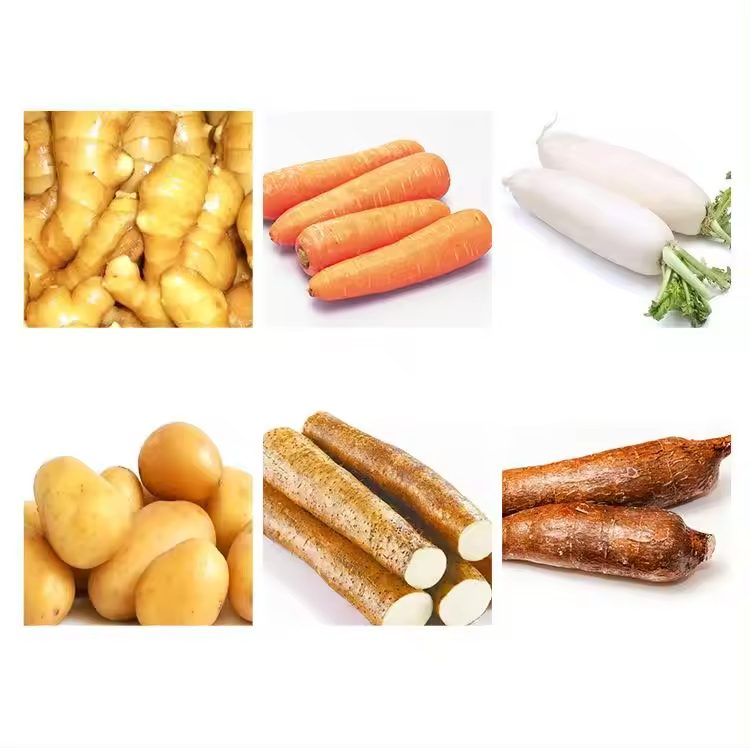

Types of Root Vegetables and Their Processing Needs

Vegetable Processing Needs:

1. Cleaning: The primary function of our machine is to clean root vegetables efficiently. Whether you’re dealing with soil-covered potatoes or muddy carrots, our machine can handle the task with ease, ensuring that your vegetables are hygienic and safe for consumption.

2. تجفيف: After cleaning, vegetables need to be dried before further processing or storage. Our machine offers optional drying capabilities, allowing you to remove excess moisture from the vegetables quickly and effectively. This not only improves shelf life but also prevents bacterial growth.

3. Slicing and Dicing: In addition to cleaning, our machine can be customized to meet your slicing and dicing requirements. Whether you need uniformly sliced potatoes for french fries or finely diced carrots for salads, our machine can deliver precise results, saving you time and effort in the kitchen.

What Makes the Root Vegetable Cleaning Machine User-Friendly?

Its easy maneuverability, simplified operations and low maintenance ensure that it is an attractive option to buyers, regardless of the scale of their operations.

في ملخص, root vegetable cleaning machines are a must-have for any agricultural business that wants to streamline its post-harvest processing operations. With their ability to clean a wide range of vegetables quickly and efficiently, they are a powerful tool that can help take your business to the next level.

ماكينة غسيل الخضار

ماكينة غسيل الخضار